With the largest installed base of US-made in-line vertical ovens in the world, Heller is the preferred choice of many leading electronics manufacturers. In-line, vertical automation of the epoxy cure process produces immediate, significant benefits in productivity, quality, and floor space reduction. Higher Productivity with In-line Processing & In-line processing provides the highest productivity by eliminating wasted time and labor needed to load and unload batch ovens, and saves time from not needing to wait for the oven to warm up. Full and semi automation options are available. Improved Process Consistency & Continuous in-line processing eliminates temperature fluctuations caused when batch oven doors are opened for loading and unloading, and forced convection heating provides consistent, uniform profiles. Improved process consistency means improved product quality.

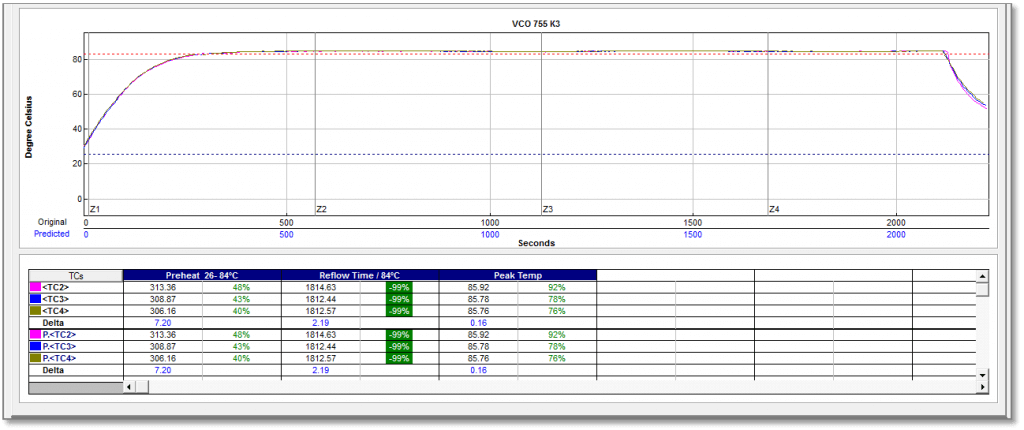

A 30 minute curing profile with exceptional temperature uniformity taken on Vertical Curing Oven 755 K3. Less Floor Space Required & the Vertical format optimizes floor space. As floor allocation costs rise on all factory floors, and particularly with clean rooms, a vertical format oven can provide cure cycles for hours with as little as six feet of floor space.

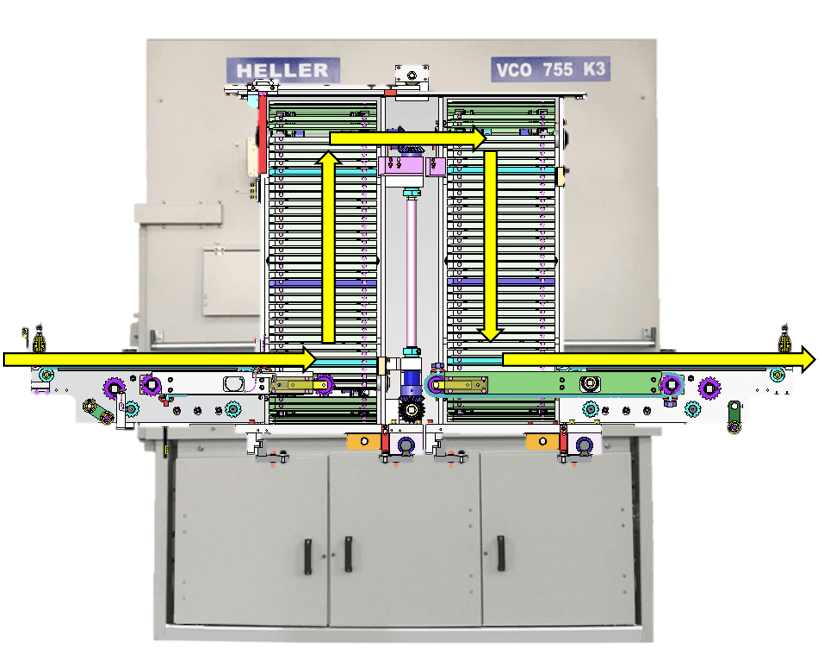

Board movement in a Vertical Curing Oven – 755 K3